Printing knowledge: Paper Characteristics

Printing knowledge: Paper Characteristics

Basic Size and Basis Weight

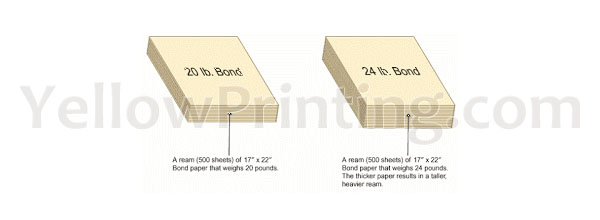

The basis weight refers to the weight in pounds of 500 sheets of paper when it has been cut to that paper's standard basic size. For example the basic size for Bond paper is 17 x 22 inches. If 500 sheets (a ream) of Bond is cut to its basic size of 17 x 22 inches and weighs 20 pounds, it is classified as 20 lb. bond. If a 17 x 22" ream of Bond paper weighed 24 pounds it would be called 24 lb. Bond, and so on. The chart below contains some common paper types and their basic size.

| Paper Type | Basic Size |

| Bond Ledger Offset Book Cover Index Vellum Printing Tag | 17" x 22" 17" x 22" 25" x 38" 25" x 38" 20" x 26" 25-1/2" x 30-1/2" 22-1/2" x 28-1/2" 22-1/2" x 28-1/2" 24" x 36" |

ISO Size Standards

The International Organization for Standardization (ISO) has established standards for paper sizes based on the metric system (millimeters). The standards have been grouped into three different series of requirements: "A-series", for general printing, "B-series", for posters, and "C-series", for envelopes, postcards, and folders. The "A" series is the most commonly used with sizes ranging from A0, which is the largest, down to A8.

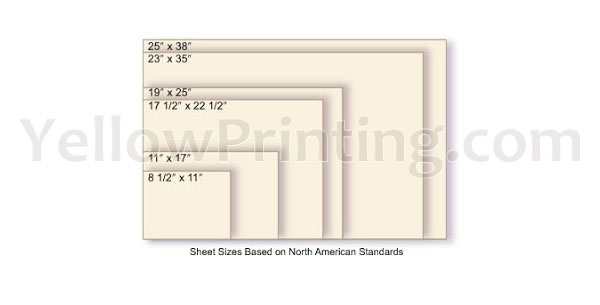

Although the ISO size standards are common in many parts of the world where the metric system is the established standard for measurement, North American sheet sizes are based on inches and are shown in the illustration below.

The paper rolls shown below are the standard widths used on web presses. The illustration also shows the standard ISO sheet sizes and the standard North American sheet sizes that can be obtained from each roll width  .

.

.

.Caliper Readings

The chart below shows the actual thickness of various weights and grades of paper. The readings are taken with a caliper or micrometer gauge, which measures the thickness of the paper in thousandths of an inch.

Paper Type | Thickness | Paper Type | Thickness |

15 lb. Bond 20 lb. Bond 24 lb. Bond | 0.003 0.004 0.0045 | 100 lb. Tag 125 lb. Tag 150 lb. Tag | 0.0075 0.009 0.0107 |

28 lb. Ledger 32 lb. Ledger 36 lb. Ledger | 0.005 0.00525 0.00575 | 4 Ply Railroad Board 6 Ply Railroad Board 8 Ply Railroad Board | 0.018 0.024 0.03 |

50 lb. Regular Offset 60 lb. Regular Offset 70 lb. Regular Offset 50 lb. Smooth Offset 60 lb. Smooth Offset 70 lb. Smooth Offset | 0.004 0.0045 0.005 0.0025 0.003 0.004 | 50 lb. Gloss Coated Book 60 lb. Gloss Coated Book 70 lb. Gloss Coated Book 80 lb. Gloss Coated Book 100 lb. Gloss Coated Book 120 lb. Gloss Coated Book | 0.0025 0.003 0.0035 0.004 0.005 0.006 |

90 lb. Index 110 lb. Index | 0.007 0.0085 | 50 lb. Coated Cover 60 lb. Coated Cover 100 lb. Coated Cover | 0.00475 0.006 0.0095 |

Finish

The finish refers to the surface characteristics of the paper such as how the paper feels...is it smooth such as glossy cover or rough with an antique finish? Does the paper have a glossy appearance such as coated glossy papers or is it dull like bond paper. Does the paper enhance the look of the printed piece similar to watermarked paper or is it purely functional like newsprint? Does the paper have a high ink absorption rate as does Vellum or poor absorption such as on coated papers?

· Cockle - A cockle finish simulates characteristics of hand made paper with a wavy, rippled, puckered finish. The effect is obtained by air drying the paper under minimum tension.

· Felt - Felt is a soft texture on uncoated paper that is created during the paper-making process with a either felt covered roller or with a rubber roller with a felt pattern that creates the finish. It can also be accomplished as an offline process. The felt finish does not affect the strength of the paper.

· Gloss - A gloss finish produces a shiny and reflective surface on one or both sides of certain coated papers. A higher gloss is usually seen on higher quality coated papers. The gloss finish is produced from compounds added during the paper making process.

· Laid - A laid finish has the appearance of translucent lines running horizontally and vertically in the paper. It is produced during the paper-making process with a special roller that creates the pattern in the wet paper.

· Linen - Linen finished paper resembles linen cloth and is usually produced after the paper-making process as an offline embossing process.

· Matte - A finish on certain coated papers that is smooth but gives a dull appearance. A matte finish, as well as other types of coated paper, are good choices for print jobs in which high quality is required.

· Parchment - A paper finish that has an old or antique appearance and is the result of washing sulfuric acid over the paper and then quickly neutralizing the acid wash. This process melts the outer paper fibers which fill the voids in the rest of the paper. Parchment is very durable and grease resistant.

· Smooth - A smooth finish is the result of the paper passing through sets of rollers during the paper-making process. This process is known as calendaring.

· Vellum - A vellum finish has an eggshell appearance and is consistent and even but not as much as a smooth finish. Vellum is one of the most popular uncoated finishes and paper with this finish has a high ink absorbency rate.

· Wove - An even finish in uncoated paper with a slight texture made by a felt roller covered in woven wire.

Grain

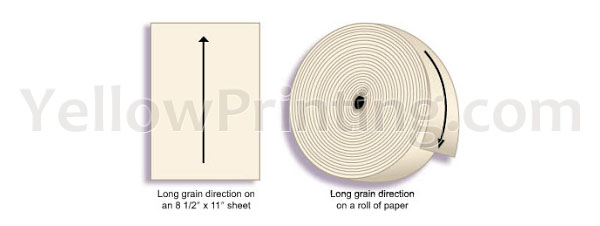

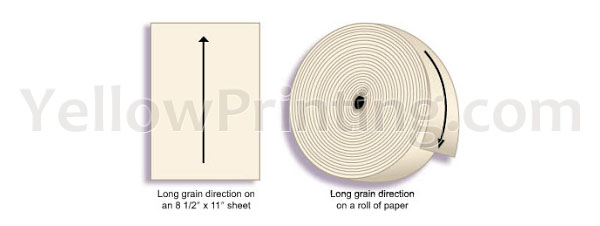

The grain of the paper refers to the direction of the fibers in a sheet of paper. Long grain paper refers to paper in which the fibers run in the same direction as the longest measurement of the paper. On rolls of paper for web presses, the grain runs along the length of the web. Short grain paper refers to paper in which the fibers run in the same direction as the shortest measurement of the paper. When paper is torn, it will tear easier and straighter when torn parallel with the grain. It will also fold easier parallel to the grain and produce a cleaner fold than if folded across the grain. Laser printers require long grain paper for the best results. Short grain paper may not feed properly into a laser printer and the heat produced by a laser printer may result in the sheets curling as they come out of the printer.

The whiteness of paper is the measure or its ability to reflect the colors of light equally. The more evenly a paper reflects all colors of the spectrum, the whiter the sheet. Some papers may reflect slightly cool colors back to our eyes and give the illusion that the sheet is actually brighter than white paper. If white paper has a slight warm appearance it will not appear as bright as a sheet that reflects a cool color, however warm colors printed on a warm sheet will appear stronger than when printed on a cool sheet. Cool colors printed on a cool white sheet are also enhanced in the same way. There is no such thing as a pure white sheet of paper, since the white that we see is always influenced by the lighting of our environment and the reflections from surrounding objects.

Grade

The grade of a paper refers to the type or category of the paper contents which provide a level of brightness or surface characteristics used to determine the grade level of the finished paper stock. Grades are classified from "Premium" at the highest level to "5" at the lowest level. Some text and cover stocks are listed simply as A or B grades since fewer grades of the text and cover stock are produced. A table illustrates the grade levels of paper according to the degree of brightness.

Brightness

Brightness refers to the percent of light reflected back from a sheet of paper as measured by a light meter reading. Contrast is reduced and highlights are not as strong when paper with a lower brightness is used for a printed piece. The quality and brightness of paper is organized into six categories:

| Paper Brightness | |||

| Premium Number 1 Number 2 Number 3 Number 4 Number 5 | Quality Quality Quality Quality Quality Quality | = = = = = = | 88.0 to 95.0 Brightness 85.0 to 87.9 Brightness 83.0 to 84.9 Brightness 79.0 to 82.9 Brightness 73.0 to 78.9 Brightness 72.9 and below |

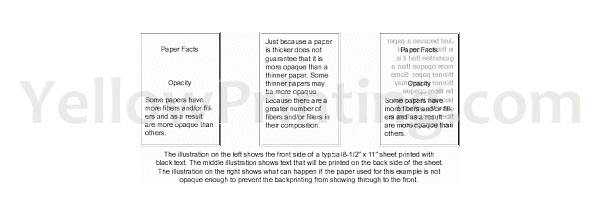

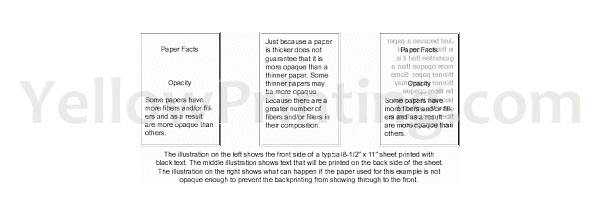

Opacity

Opacity is the measure (percent) of the amount of light passing through a sheet of paper. Some papers have more fibers and/or fillers and as a result are more opaque than others. Papers containing more fibers and fillers have the ability to hold a printed image without showing through to the backside as easily as papers without as many fibers and fillers. Just because a paper is thicker does not guarantee that it is more opaque than a thinner paper. Some thinner papers may be more opaque because there are a greater number of fibers and/or fillers in their composition.

The smoothness level is a measure of the surface characteristics of paper. The flatter or more even the surface, the higher the level of smoothness. With a smoother surface, the stock can provide a fully shaped ink dot resulting in a sharper and higher quality image.

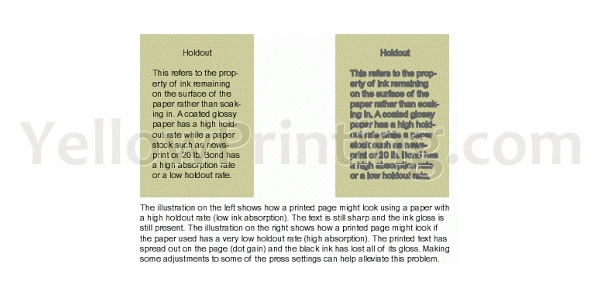

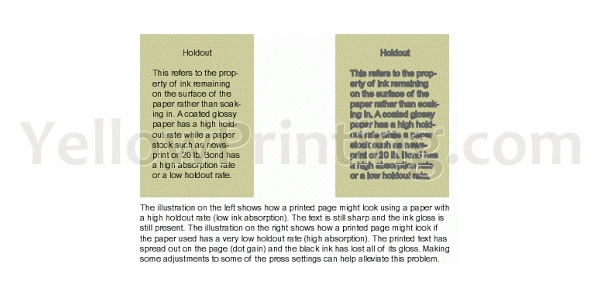

Holdout

Holdout refers to the property of ink remaining on the surface of the paper rather than soaking in. A coated glossy paper has a high holdout rate while a paper stock such as newsprint or 20 lb. Bond has a high absorption rate or a low holdout rate.

The pH (potential for Hydrogen) measurement of paper determines the degree of acidity and alkalinity in the stock. The pH scale has readings of 0 to 14 with 7 being neutral. Readings

YellowPrinting: If you copied it to elsewhere, please show the original source of this article, thanks.